Quality according

to Scherini

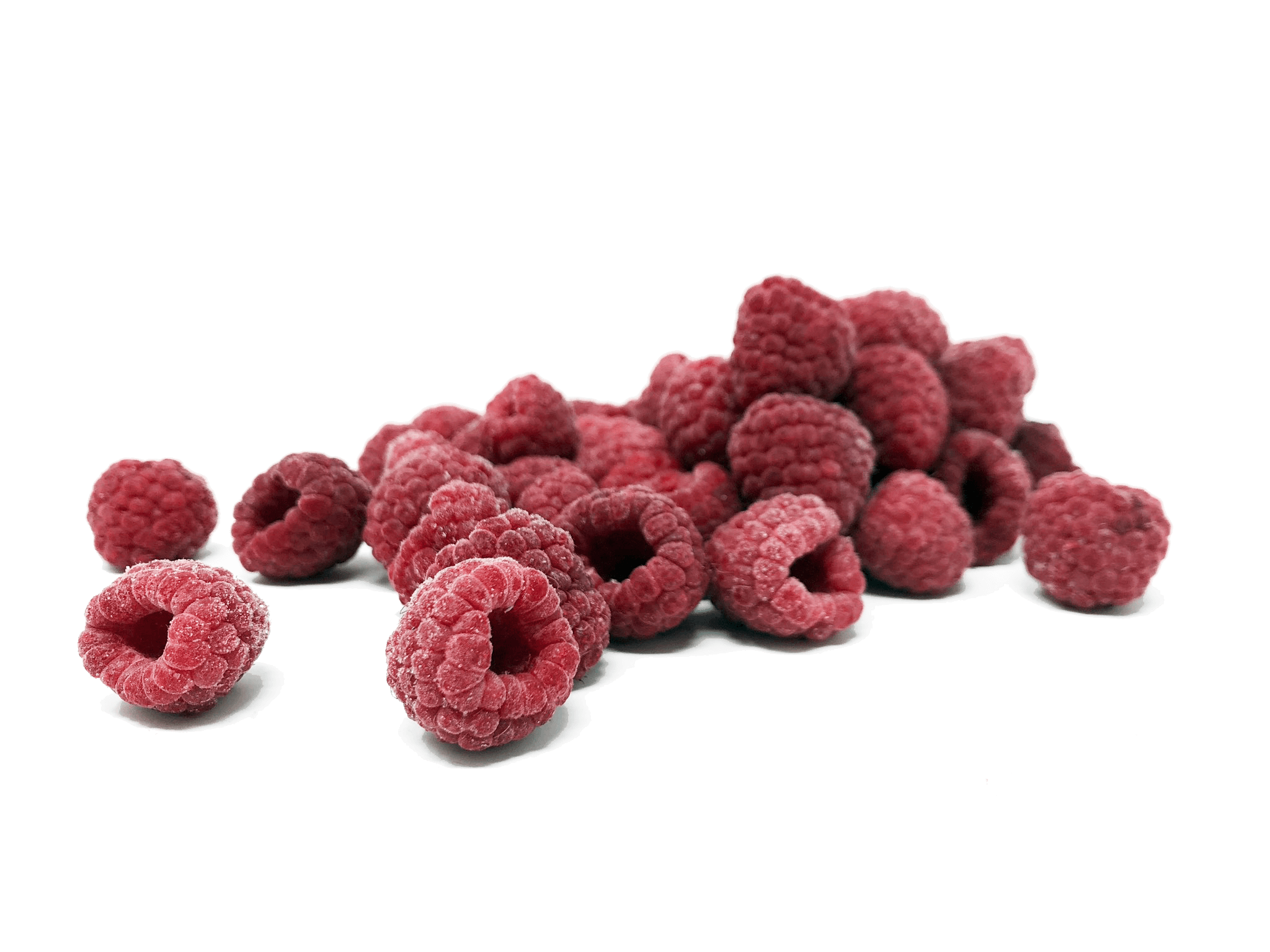

Today, the issue of food safety is more important than ever. For us, the pursuit of quality has always been a priority that begins from afar: it means carefully selecting our growers and harvesters, building relationships based on mutual trust, inspecting the products throughout all of their transformation phases, and guaranteeing the complete traceability of the raw materials.

Quality cannot be improvised: we’ve been building it for fifty years, day after day.

Safe and

certified products

The safety and quality of Scherini frozen foods are evidenced by two of the main international certifications for the sector: IFS (International Food Standard), the large-scale retail food certification that sets the requirements for every raw material production and processing phase, and BRC Food, the global food safety standard that ensures the quality of agri-food products.